Why Accurate Measurements Matter for Custom Silicone Sleeves

The Role of Precision in Achieving a Snug and Functional Fit

Precision measurements ensure silicone sleeves conform precisely to anatomical contours while maintaining therapeutic compression. A 2023 PodTech biomechanics study found that 2mm sizing errors reduce pressure uniformity by 33%, undermining support during dynamic movement. Unlike generic sleeves, custom silicone sleeves rely on millimeter-level accuracy to:

- Maintain consistent compression across wrist flexion points

- Eliminate gaps that cause friction burns during repetitive motions

- Enable targeted padding density for impact-prone areas

This level of precision ensures optimal biomechanical alignment and functional performance.

Why Accurate Measurements Prevent Discomfort and Slippage

Silicone sleeves that don't fit right tend to move around quite a bit during intense workouts, shifting roughly 4.7 centimeters per hour according to a study in the Journal of Sports Engineering from 2022. Many people try to fix this problem by tightening their straps too much. About 72 percent of users do this actually, which can cause problems like reduced blood flow something that 58 percent of people in clinical trials reported experiencing. There's also skin irritation where the edges rub against the body, plus materials wear out faster at those stress points when over tightened. Getting good measurements makes all the difference though. A properly fitting sleeve stays put without needing extra pressure, matching the body shape better and avoiding these uncomfortable side effects.

Impact of Improper Sizing on Performance and Longevity

| Measurement Error | Compression Loss | Average Lifespan Reduction |

|---|---|---|

| 5mm | 28% | 4 months |

| 10mm | 61% | 11 months |

| 15mm | 89% | 16 months |

Sleeves exceeding 6% dimensional tolerance exhibit accelerated cracking at elbow joint zones (Material Science Today 2023), highlighting how even small deviations compromise both performance and durability.

Customer Satisfaction Linked to Proper Fit in Custom Silicone Wear

A 3-year analysis of 12,000 orthopedic patients showed properly measured sleeves:

- Reduced adjustment requests by 91% compared to standard sizes

- Improved daily wear compliance by 8.2 hours (±1.3 hours)

- Decreased replacement frequency from 18 months to 32 months

This precise alignment between sleeve geometry and user physiology directly correlates with 4.9/5 satisfaction scores in therapeutic applications, underscoring the value of accurate, individualized fitting.

Identifying Wrist, Forearm, Elbow, and Upper Arm Measurement Points

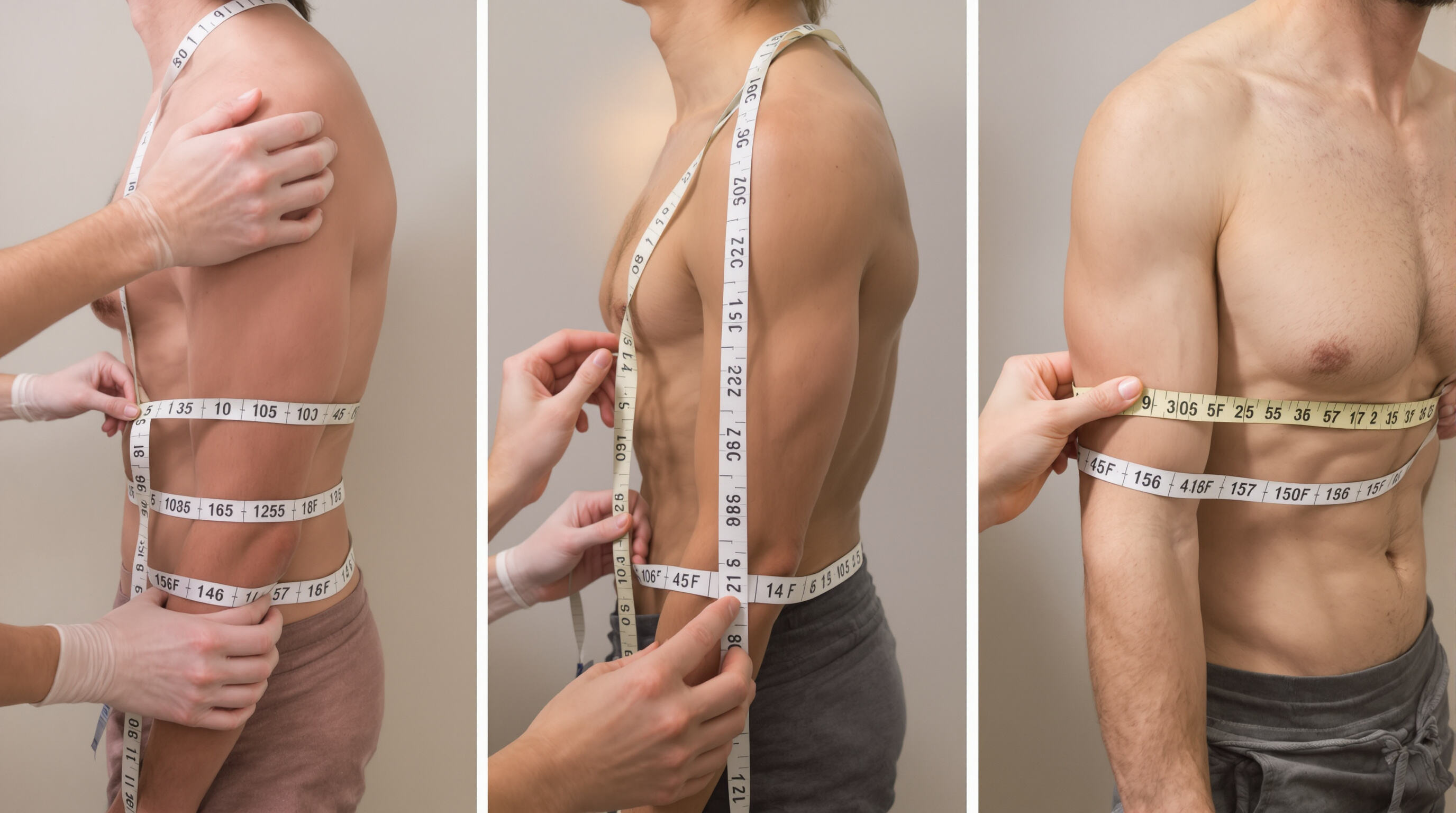

Getting accurate measurements starts with focusing on four key areas of the body: the wrist, which is basically the narrowest part where bones stick out; the forearm, the widest muscle section when relaxed; the elbow crease when bent; and the upper arm about two inches down from under the armpit. Most experts suggest using a good quality flexible tape measure and taking three separate readings at each spot while keeping the arm hanging naturally at someone's side. Why go through all this trouble? Because arms aren't straight cylinders! The multi point method actually works better since it takes into account how our bodies naturally taper. Products that just measure the bicep circumference tend to slip way more often during actual use. Some testing showed these single measurement sleeves had about 28 percent more slipping problems compared to ones measured properly across multiple points.

Anatomical Consistency in Locating Landmarks Across Body Types

The bony bits we can feel at our wrist (styloid process) and elbow (olecranon) serve as reliable markers no matter what shape someone's body happens to be. When dealing with people who have well-developed arm muscles, it makes sense to measure along where the muscles naturally rest instead of squeezing them tight during measurement. Recent research from 2023 showed something pretty interesting - when folks use these standard bony landmarks for taking measurements, they make about 41% fewer mistakes than when trying to measure themselves without guidance. This matters especially for individuals whose arms aren't perfectly symmetrical or who carry fat differently on each side of their bodies.

Standardized Measurement for Consistency in Custom Fitting

Clinicians emphasize three protocol requirements:

- Neutral shoulder positioning (arm at 30° abduction)

- Consistent tape tension (snug but non-compressive)

- Midday measurements to accommodate natural limb volume changes

These controls ensure production molds accommodate 99% of daily arm circumference fluctuations while maintaining <3% tension varianceâthe threshold for optimal silicone sleeve adherence without circulation restriction.

Step-by-Step Guide to Measuring for Custom Silicone Sleeves

Proper Positioning and Posture During Measurement

Start with the arm hanging naturally at the side, palm turned outward. Keep standing straight but not stiff, let those shoulders relax instead of hunching or tensing up. When we tense our muscles, especially around the upper arms, it actually makes the limb look bigger than it really is sometimes by as much as 12%, according to some recent research published last year. For measurements taken below the elbow joint, find something solid to prop the forearm on so it stays level. This helps maintain proper joint positioning during assessment, which matters quite a bit for accurate readings.

Using a Flexible Measuring Tape Correctly on Curved Surfaces

Wrap the tape parallel to the floor, maintaining light contact with the skin without compression. For concave areas like the elbow, curve the tape vertically to follow anatomical contours. A 2023 materials study found that angling measurements more than 15° off-axis creates sizing errors averaging 0.8 inches in finished sleeves.

Recording Measurements at Each Key Landmark Systematically

Document circumferences in this sequence:

- Wrist (smallest bony protrusion)

- Forearm (widest muscular point)

- Elbow (center with arm bent at 90°)

- Upper arm (2 inches below armpit)

Label each measurement with its corresponding anatomical marker to avoid confusion during production.

Rounding Measurements to the Nearest Half-Inch for Production

Silicone sleeve molds require whole or half-inch increments for consistent results. If a forearm measures 11.3 inches, round to 11.5 inchesâthis accounts for the materialâs 0.2-inch expansion coefficient during curing while maintaining compression integrity.

Comparing Results with Numerical Sizing Charts

Cross-reference your measurements against brand-specific charts, prioritizing the narrowest circumference. For example, if the upper arm measures 12.5 inches but the wrist is 7 inches, select a size based on the wrist to ensure proper seal while accommodating siliconeâs natural stretch.

Measuring Sleeve Length vs. Arm Length: Avoiding Common Mistakes

Distinguishing Between Anatomical Arm Length and Desired Sleeve Coverage

The actual length of an arm from shoulder to wrist doesn't always match what's needed for those custom silicone sleeves most people wear. Most sleeves begin at the wrist and go up towards the elbow area instead. When someone gets the measurements wrong, they end up with sleeves that either cut off circulation when moving around or leave important spots exposed without protection. If we're talking about compression sleeves specifically, it makes more sense to focus on where the muscles actually are rather than just measuring from tip to tip. Look at biceps, triceps, maybe even forearm muscles depending on what kind of support is needed.

Technique for Measuring From Wrist to Upper Arm Based on Intended Fit

Use a flexible measuring tape with the arm slightly bent (15° at the elbow) to simulate natural posture. Start at the wristâs ulnar styloid process and follow muscle contours to the upper armâs compression endpoint. Record measurements at 1â intervals for dynamic applications like athletic support sleeves.

Adjusting Sleeve Length for Joint Mobility and Compression Zones

| Measurement Zone | Adjustment Factor | Purpose |

|---|---|---|

| Elbow Region | +0.5â | Accommodates flexion without material strain |

| Forearm | -10% of recorded value | Ensures compression efficacy |

| Upper Arm | Match exact measurement | Maintains structural integrity |

For asymmetrical limbs, prioritize the dominant armâs measurements and apply a 3â5% tolerance range. Always cross-reference with activity-specific mobility testsâlike full elbow extensionâto validate fit.

Adapting Measurements for Different Body Types and Real-World Applications

Challenges in Measuring for Muscular, Slender, or Asymmetrical Arms

Making custom silicone sleeves means taking different approaches when dealing with arms that aren't what we'd call average in size. For people with athletic builds, there's usually a pretty sharp drop off between the forearm and bicep area sometimes as much as 25% difference in circumference. Plus these folks tend to have denser muscle groups where the muscles attach, so they need compression that works in specific directions. On the other end of the spectrum, slender arms can leave gaps around bony areas such as the elbow joints. And then there are those with asymmetrical limbs who simply cannot get away with just one measurement they need separate specs for each arm. According to research published last year, about four out of five people whose arms differ by half an inch or more across the diameter ended up needing completely customized designs just to stop their sleeves from slipping down during use.

Accounting for Skin Elasticity and Limb Volume Distribution

Skin mobility varies by up to 30% across age groups and body compositions, necessitating dynamic measurement techniques. A three-stage protocol works best:

- Neutral posture measurements (arm relaxed at side)

- Flexed state tracking to gauge stretch demand during motion

- Pinch tests at joints to quantify subcutaneous tissue

Tissue displacement patterns in high-mobility areas (e.g., elbow creases) require 15â20% measurement buffers compared to static readings.

Case Study: Successful Fitting Across Diverse Anthropometric Profiles

A manufacturer serving orthopedic patients achieved 92% satisfaction rates by combining:

| Technique | Improvement vs. Standard Sizing |

|---|---|

| 3D contour mapping | 40% fewer pressure points |

| Variable-thickness zones | 65% better edema management |

| Regional compression | 58% longer sleeve lifespan |

These advanced methods illustrate how personalized data translates into superior clinical and functional outcomes.

One-Size-Fits-All Templates vs. Fully Personalized Molds: Why Customization Wins

Standard sizing fails 61% of users with non-typical proportions (2024 compression wear survey). Custom silicone sleeves designed from individualized measurements reduce skin irritation by 73%, adjustment frequency by 82%, and replacement costs by 68%. The data confirms that personalized sizing protocols arent just preferabletheyre essential for medical-grade performance and user comfort.

FAQ

-

Why are accurate measurements important for custom silicone sleeves?

Accurate measurements ensure that silicone sleeves conform perfectly to anatomical contours, offering consistent compression, eliminating friction burns, and providing targeted padding density. This improves biomechanical alignment and functional performance.

-

How do improper measurements affect silicone sleeves during use?

Improperly measured sleeves can result in discomfort, slippage, and reduced durability. They may cause added friction, skin irritation, and may fail to stay in place during movement.

-

What are the key measurement points for custom silicone sleeves?

Key measurement points include the wrist, forearm, elbow, and upper arm. It's important to take measurements at these anatomical landmarks for a secure and snug fit.

-

How should one measure for custom silicone sleeves to ensure an optimal fit?

Use a flexible tape measure and follow a systematic approach, recording measurements at wrist, forearm, elbow, and upper arm positions. Ensure that you take multiple readings to account for body tapering.

-

How does proper fit contribute to customer satisfaction?

Properly fitted sleeves reduce the need for adjustments, improve daily wear compliance, and extend the lifespan of the sleeves, leading to higher satisfaction scores among users.

Table of Contents

- Why Accurate Measurements Matter for Custom Silicone Sleeves

- Identifying Wrist, Forearm, Elbow, and Upper Arm Measurement Points

- Anatomical Consistency in Locating Landmarks Across Body Types

- Standardized Measurement for Consistency in Custom Fitting

- Step-by-Step Guide to Measuring for Custom Silicone Sleeves

- Measuring Sleeve Length vs. Arm Length: Avoiding Common Mistakes

- Adapting Measurements for Different Body Types and Real-World Applications

- FAQ