Understanding the Custom Silicone Strips Manufacturing Process

The Silicone Extrusion Process: From Raw Material to Continuous Profile

Most manufacturers start off using either high consistency rubber (HCR) or liquid silicone rubber (LSR). They heat these materials until they become soft enough to work with during the extrusion process. What happens next? Well, the softened material gets pushed through specially made dies at pressures ranging from about 50 to 200 bars. This creates long continuous shapes that can stretch out over 100 meters in length. After this initial shaping comes the curing stage. The profiles need to go into industrial ovens where temperatures range between roughly 150 and 300 degrees Celsius (which translates to around 302 to 572 Fahrenheit). An interesting difference here is that LSR tends to cure much quicker than HCR materials. We're talking about about 70% faster actually, thanks to those special platinum catalysts working their magic in the chemical reactions.

| Material Type | Curing Method | Tensile Strength | Typical Use Case |

|---|---|---|---|

| HCR | Peroxide | 8–12 MPa | High-temp seals |

| LSR | Platinum | 5–9 MPa | Medical devices |

Role of Mold Design and Extrusion Dies in Shaping Custom Silicone Profiles

Extrusion dies made with precision machining can hit tolerances around +/- 0.1 mm, something really important when manufacturing seals for things like airplanes or medical devices where exact dimensions matter. The use of computational fluid dynamics has changed how these dies are designed, cutting down on wasted materials by roughly 18% over older techniques according to industry reports. What makes these dies work so well? They come with special flow channels that stop air bubbles from getting trapped in those U-shaped seal sections. There are also adjustable lips that let manufacturers tweak wall thicknesses for different parts of multi-material strips. And don't forget the retractable pins that make production possible for those hollow core tubes used in vacuum systems across various industries.

How Precision and Tolerance in Manufacturing Affect Final Product Quality

A 2023 study found that 92% of seal failures result from tolerance deviations exceeding ±0.25 mm. Modern extrusion lines use laser micrometers to measure profiles at 200 points per second, enabling real-time adjustments. This ensures compression set variation remains below 5% across batches—critical for automotive weatherstripping designed to last 15 years.

Design Considerations for Optimal Custom Silicone Profiles

Material Selection and Durometer: Matching Silicone Properties to Application Needs

Picking the correct silicone material means finding the sweet spot between hardness (durometer), how it handles heat, and whether it plays nice with chemicals. For medical stuff like implants or devices that touch body tissues, most folks go with platinum cured silicones that have around 50 Shore A hardness or less because they're safer inside the body. Industrial applications tell a different story though. Seals and gaskets usually need something tougher, so they opt for silicones in the 70 to 80 Shore A range which stands up better under pressure over time. When looking at materials specs, don't forget those environmental factors either. Things like sunlight exposure, contact with ozone, and repeated mechanical stress all matter a lot during the design phase. These conditions actually determine what kind of polymer base works best and how exactly it should be processed through curing techniques.

Tolerance, Flexibility, and Compression Set: Key Factors in Custom Silicone Strips

Precision engineering ensures consistent performance in custom silicone strips:

- Tolerances as tight as ±0.1 mm prevent leakage in sealing applications

- Flexibility (200–500% elongation) accommodates irregular surfaces

- Compression set ⩽10% (per ASTM D2000-2023) guarantees long-term elasticity

Designers must consider these parameters holistically—a 70 Shore A strip with high compression resistance may compromise vibration dampening if flexibility limits are exceeded.

Designing for Dynamic Environments: Gaskets and Seals Under Stress

When it comes to silicone profiles used in areas with lots of movement, engineers typically turn to finite element analysis or FEA for short. This helps them figure out how stress spreads through the material. Automotive manufacturers have found that when they optimize the shape of these profiles, they can cut down on peak strain by about 40% even after their door seals go through around 10 million compression cycles. In situations where temperatures swing wildly between -60 degrees Celsius and 230 degrees Celsius, designers usually build in special features like thermal breaks and those curved stress relief areas. These modifications help maintain strong adhesion properties, with tests showing that over 95% of the original stickiness remains intact after five years of service in aerospace contexts according to the latest data from the 2022 Materials Performance Report.

Advanced Fabrication Techniques for Custom Silicone Strips

Die Cutting and Precision Shaping for Complex Silicone Geometries

Die cutting produces intricate shapes using steel rule dies, achieving ±0.2 mm tolerances for medical seals and automotive gaskets. Computer-controlled systems reduce material waste by 18% compared to manual methods. Rotary die cutting is ideal for high-volume production, delivering 500–1,200 parts per hour with consistent edge quality.

Laser and Waterjet Cutting: Balancing Accuracy and Thermal Impact

Laser cutting offers micron-level precision (down to 0.05 mm), but requires thermal control to avoid silicone degradation. Waterjet cutting eliminates heat risks but has slightly wider tolerances (±0.3 mm). Advanced hybrid systems use lasers for fine details and waterjets for bulk cutting, improving throughput by 30–40% in aerospace sealing applications.

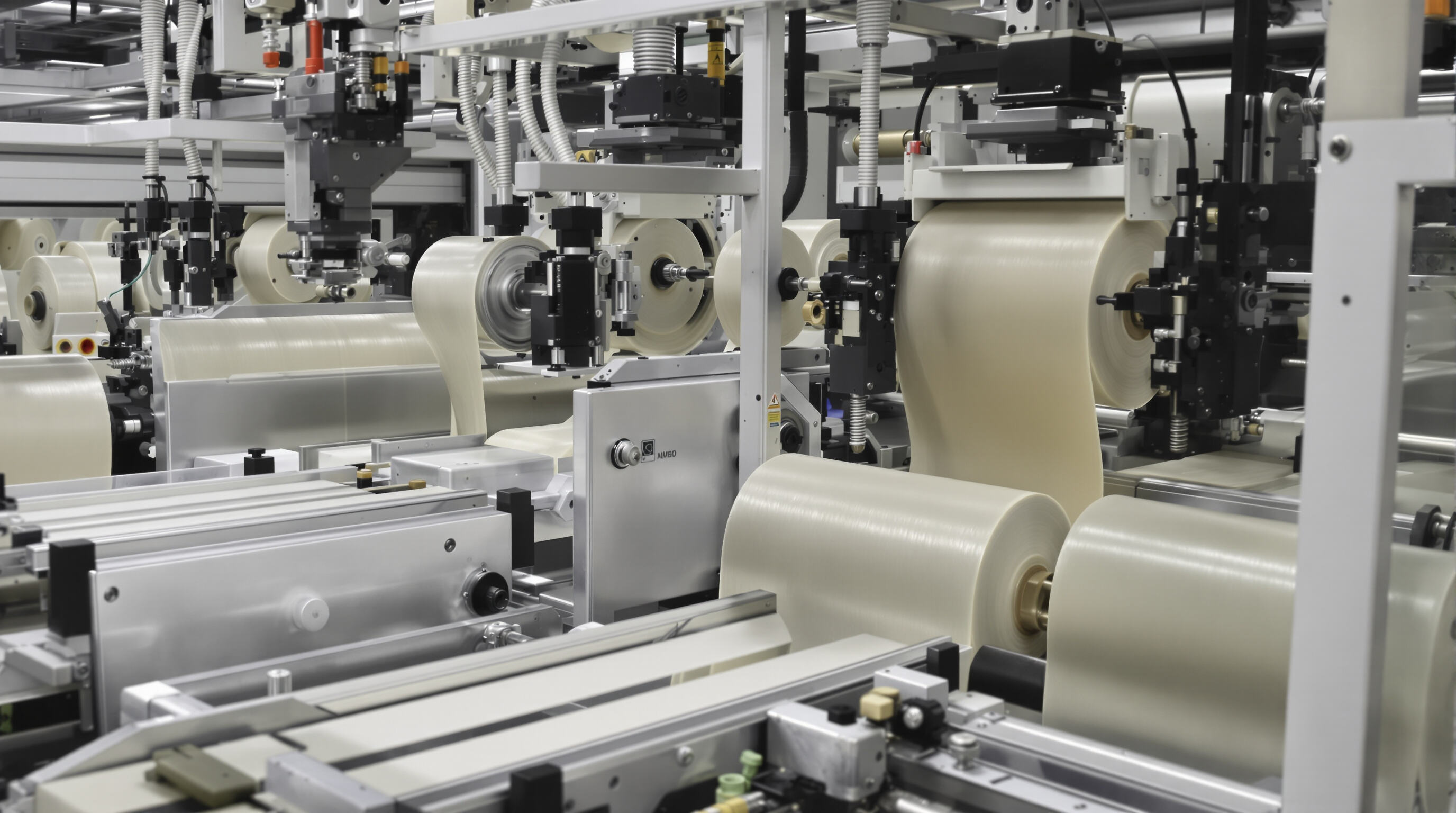

Slitting and Cutting for Automated Assembly and Specialized Widths

Precision slitting creates strips as narrow as 0.5 mm with tolerances under ±0.1 mm. Tension-controlled systems ensure uniformity across rolls exceeding 1,000 meters, supporting automated installation in electronics manufacturing. Servo-driven cutters handle 3–5 slitting patterns without tool changes, reducing setup time by 65% in industrial gasket production.

Integrating Secondary Processes Through Custom Converting

Combining Extrusion with Adhesive Lamination, Splicing, and Coiling

Post-extrusion processes enhance functionality. Adhesive lamination applies pressure-sensitive tapes to profiles, enabling quick installation in automotive and appliance seals. Precision splicing connects strips end-to-end for continuous sealing in conveyor systems, while automated coiling prepares ready-to-use rolls that cut assembly time by up to 40% in electronics manufacturing.

Custom Converting for Enhanced Product Integration and Performance

Secondary processes transform extrusions into application-ready components:

- Die-cut adhesive backers match complex gasket geometries with ±0.2 mm accuracy

- Plasma-treated surfaces boost bond strength by 30% in metal-silicone assemblies

- Perforated release liners support automated dispensing in high-speed lines

Converted silicone products command 22% higher profit margins than raw extrusions due to added functionality, according to a 2023 Grand View Research study.

Case Study: Custom Silicone Strips in Medical Device Sealing Systems

A leading infusion pump manufacturer needed FDA-compliant seals capable of 10,000 compression cycles. Through custom converting, a 55-durometer silicone strip with medical-grade adhesive achieved zero fluid ingress at 35 PSI in ISO 13485:2016 testing. The laminated design reduced assembly errors by 37% compared to manual adhesive application.

Ensuring Quality and Consistency in Custom Silicone Profile Production

Testing for Dimensional Accuracy and Material Integrity in Silicone Strips

Coordinate measuring machines (CMM) verify thickness, width, and cross-sectional geometry within ±0.05 mm—essential for sealing performance. Tensile testing confirms elongation rates of 300–500% and compression set below 15%, meeting ISO 9001 standards. Automated vision systems inspect 100% of production runs for microtears or surface defects, ensuring reliability in medical-grade fluid containment applications.

Maintaining Batch-to-Batch Uniformity in Extruded Custom Silicone Profiles

The process validation actually involves tracking around 50 key parameters throughout production. Things like extrusion speed needs to stay within half a percent variance, temperature zones must be controlled to within one degree Celsius, and curing times need strict monitoring too. With real time statistical process control systems in place, we can monitor how viscous the raw materials are getting and tweak the filler ratios on the fly so shore hardness stays no more than two points away from what we're aiming for. Maintaining this kind of consistency really matters because it stops those annoying fluctuations in gasket compression force that could spell trouble for manufacturers working toward ISO 13485 certification requirements for medical devices.

Balancing Customization with Scalability in High-Volume Production

Modular tooling makes it possible to switch dies quickly while keeping those profiles aligned within less than 0.1 mm throughout production runs that can stretch over 10 kilometers. The factory has implemented automated quality checks along the line using things like laser micrometers and infrared spectroscopy, which cuts down defects by around 78 percent when compared to old fashioned manual sampling methods according to research published last year in the Polymer Processing Journal. What's really impressive is how this system handles custom jobs ranging anywhere between 500 meters all the way up to 50 kilometers long without compromising on that crucial plus or minus 2% dimensional stability needed specifically for making weather seals used in cars today.

FAQ

Q: What materials are used in custom silicone strips manufacturing?

A: Manufacturers typically use high consistency rubber (HCR) or liquid silicone rubber (LSR) for silicone strips.

Q: How does mold design affect the extrusion process?

A: Precision mold design is crucial as it influences the exact dimensions and quality, reducing wastage by about 18%.

Q: What testing ensures quality in silicone profile production?

A: Quality checks include dimensional accuracy tests, tensile testing, and automated vision systems for defect inspection.

Table of Contents

- Understanding the Custom Silicone Strips Manufacturing Process

- Design Considerations for Optimal Custom Silicone Profiles

- Advanced Fabrication Techniques for Custom Silicone Strips

- Integrating Secondary Processes Through Custom Converting

- Ensuring Quality and Consistency in Custom Silicone Profile Production

- FAQ