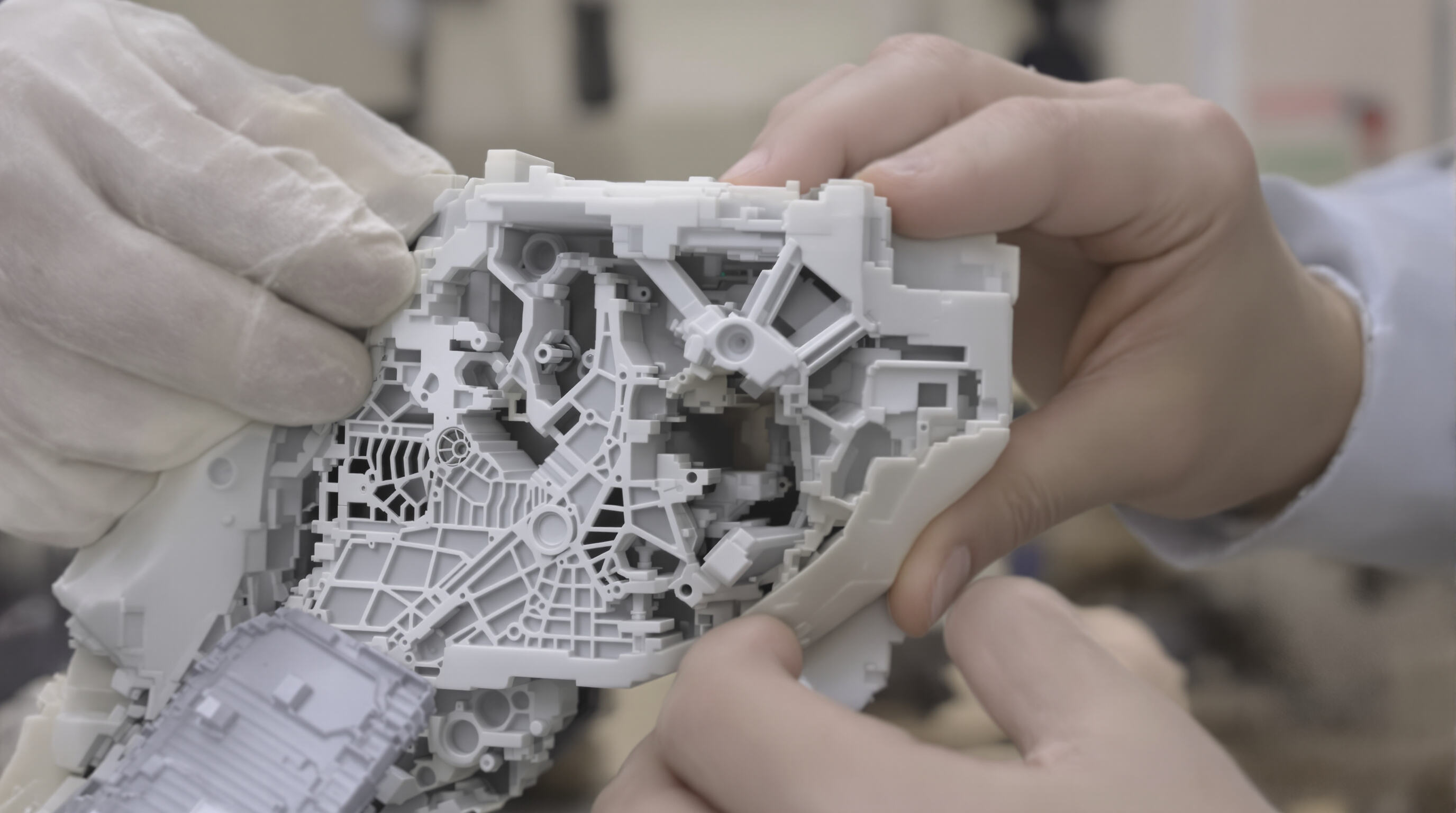

Unmatched Flexibility for Complex and Intricate Mold Designs

How Silicone's Flexibility Enables Easy Demolding Without Damage

The unique molecular makeup of silicone gives it about 50 to 70 percent elastic recovery after being deformed according to research from Polymers Journal last year. This property lets molds wrap around complex shapes without ripping apart. When it comes to demolding, flexible silicone requires roughly 40 to 60 percent less force than stiffer alternatives such as polyurethane. A study on overmolding techniques back in 2021 showed this clearly. For those making microfluidic devices, these improvements translate into real world benefits. Manufacturers have noticed something remarkable too many claim nearly 98 percent fewer defective parts simply because there's so much less friction when releasing components from the mold.

Superior Release Performance for Undercuts and Intricate Geometries

With elongation-at-break reaching up to 1,000%, silicone effortlessly separates from undercuts -1.5mm deep. This enables leading manufacturers to achieve 99.5% retention of fine features (-0.2mm), such as in hearing aid shells—geometries where traditional epoxy molds typically fail.

Silicone vs. Rigid Materials: Maintaining Structural Integrity While Remaining Flexible

| Property | Silicone Molds | Rigid Plastic Molds |

|---|---|---|

| Flexibility | 90° bend without crack | Fractures at 15° bend |

| Dimensional Stability | ±0.1mm over 500 cycles | ±0.5mm after 50 cycles |

| Demolding Success Rate | 97% (Complex Shapes) | 62% (Complex Shapes) |

Silicone maintains dimensional accuracy with less than 0.1mm deviation across 1,000+ cycles, while ABS and polycarbonate molds develop stress cracks after just 300 uses (Advanced Materials Testing 2022).

Real-World Applications Where Flexibility Prevents Part Deformation

In aerospace composite molding, silicone’s 45–55 Shore A hardness prevents warping in carbon fiber layups requiring -0.05mm tolerances. Dental labs using flexible silicone for 3D-printed crown molds have reduced post-processing time by 35 hours/month by eliminating damage during extraction of fragile acrylate surfaces.

Exceptional Detail and Texture Reproduction in Silicone Molds

Capturing Fine Details and Micro-Level Surface Textures with Precision

The unique properties of silicone let it copy really tiny textures down to about 10 to 20 microns, which is why so many industries rely on it when they need something that feels just right both to touch and see. Regular molds can't do this because they're too stiff, but silicone actually bends around complicated shapes without losing its shape, and does a great job at copying those small details like brushed metal surfaces or that rough matte finish people want these days. Sometimes this means no extra work after molding either. Doctors and medical equipment companies love using silicone for handles that won't slip out of hands during procedures. Meanwhile, phone manufacturers have started incorporating silicone into their designs too, especially for those buttons that give that satisfying click feeling when pressed.

Case Study: Replicating Artistic Reliefs and Ornate Designs

According to research published in 2024 on materials science, silicone has been found to capture around 98 percent of surface details during heritage restoration work. Artisans working on reproducing an old fashioned plaster frieze from the 1800s managed to get under 50 microns precision when making those intricate flower designs and swirling patterns. They even managed to keep all those tiny tool marks and deliberate flaws that were part of the original piece something that regular polyurethane tends to wash away by filling up every little crack and crevice. No wonder high end fashion houses prefer silicone for their special edition decorative elements that need that authentic hand carved look.

Critical Use Cases in Jewelry, Dental, and Sculpture Industries

- Jewelry: Silicone molds reproduce filigree and prong settings at -0.1mm tolerances, reducing casting defects by 73% compared to epoxy systems (2023 Jewelry Manufacturing Report).

- Dental: Digitally derived silicone bite registration molds achieve 99.5% occlusal surface accuracy for crowns and bridges.

- Sculpture: Foundries cast bronze artworks with bark textures and fabric drapery requiring <0.3mm variance from original clay models.

Industry benchmarks confirm silicone maintains texture fidelity for ¥200 cycles, far exceeding cheaper alternatives that degrade after 30–50 uses.

Durability, Reusability, and Performance Under Harsh Conditions

Heat and Chemical Resistance in Industrial Silicone Mold Applications

Silicone can handle temps above 300 degrees Celsius (around 572 Fahrenheit) and stands up to oils, solvents, and various acids better than urethane and sometimes even certain metals. What makes this possible? The material has an inorganic polymer structure that just doesn't break down when exposed to constant heating and cooling cycles. Take foundries as a good example they often rely on platinum cured silicone for casting those low melting point alloys right around 250 degrees Celsius. These molds last through hundreds of cycles without warping issues. Some real world testing shows these silicone molds actually last about 74 percent longer than their polyurethane counterparts before needing replacement.

Long-Term Reusability in Casting Processes Without Degradation

With tear strength between 12–15 kN/m², silicone endures repeated demolding while preserving detail. Food-grade molds for chocolate production retain 98% dimensional accuracy over 2,000+ cycles, unlike epoxy resins that develop microcracks after 20–30 uses. A 2023 lifecycle analysis found silicone molds reduce per-unit production costs by 31% compared to disposable plastic alternatives.

Cost-Efficiency Through Extended Mold Lifecycle

Silicone molds might cost 20 to 40 percent more upfront compared to urethane options, but they tend to outlast them by about tenfold in most industrial applications, which makes sense economically over time. The automotive industry has seen real results too - companies making rubber gaskets with high consistency silicone (HCR) instead of traditional metal tools have reported needing replacement parts only 83% less often. And there's another benefit worth mentioning: because silicone naturally releases from castings, factories can cut down on mold release agents by roughly 92%. This means significantly reduced maintenance expenses as well since composite molds typically require frequent surface treatments, whereas silicone maintains its integrity much better throughout extended production runs.

Design Versatility and Applications Across Industries

Custom Silicone Mold Options for Prototyping and Small-Batch Production

Silicone supports rapid prototyping by enabling testing of complex geometries without expensive tooling changes. Its dimensional stability during iterative design refinements makes it ideal for products like ergonomic grips or microfluidic devices. Polymer molding efficiency studies show this adaptability reduces material waste by up to 40% in early development stages.

Role of Silicone in Accelerating Product Development Cycles

Silicone’s fast curing and reusability shorten development timelines significantly. Engineers report a 55% reduction in lead times for pre-production validation, avoiding delays from machining hard tooling. Compatibility with 3D-printed masters further accelerates workflows, allowing weekly iterations instead of monthly.

Cross-Industry Applications: From Medical to Consumer Goods

Silicone's ability to work safely inside the body makes it a go to material for medical device makers who need components ready for sterilization, such as early versions of catheters. Car companies meanwhile rely on the same material for long lasting seals and parts that can handle heat under the hood. When it comes to everyday products, food safe silicone molds have become popular among crafters making special edition chocolates and hand made soaps. According to a recent industry poll from last year, around three quarters of design professionals choose silicone when they need something that works well in both small batches and large scale production across all sorts of different uses.

FAQ

- What makes silicone better for demolding intricate designs? Silicone's flexibility and high elastic recovery allow it to wrap around complex shapes, reducing the force needed for demolding, which decreases the chance of damaging intricate designs.

- How does silicone's performance compare with rigid materials in molds? Silicone outperforms rigid materials due to its flexibility, maintaining structural integrity without cracking and providing a higher demolding success rate for complex shapes.

- Can silicone molds withstand high temperatures? Yes, silicone molds can handle temperatures above 300 degrees Celsius and resist various chemicals, making them suitable for industrial applications.

- Are silicone molds cost-efficient in the long run? While initially more expensive, silicone molds have a longer lifespan, leading to significant cost savings in industrial applications over time.